Education

- B.E. Mechanical Engineering — KPR Institute of Engineering and Technology (3rd Year, expected 2027)

- Senior Secondary / Secondary: Ponnaiyah Ramajayam public school (CBSE),Kumbakonam

Experience

Bimetal Bearings Limited — R&D Intern

Assisted the Research & Development team in studying bearing design processes, material properties, and testing methods. Gained hands-on exposure to tribology concepts, material testing procedures, and mechanical performance evaluation used in bearing development.

Flow Link Systems Private Ltd— Intern

Gained practical experience with foundry operations, machining processes, and quality checks. Observed CNC and VTL operations (Mori Seiki, VMC/HMC platforms) and learned about production workflows for valve and engine components.

Projects

- Smart Fan Control — Automation project integrating PIR sensors, LM35, and ACS712 for intelligent fan control and energy feedback (LCD I2C display).

- Trash Collector — Prototype embedded project.

- Smart Blind Stick — Assistive device project for accessibility.

3D Model Showcase

Click any image to enlarge — these are renders/screenshots of my CAD models.

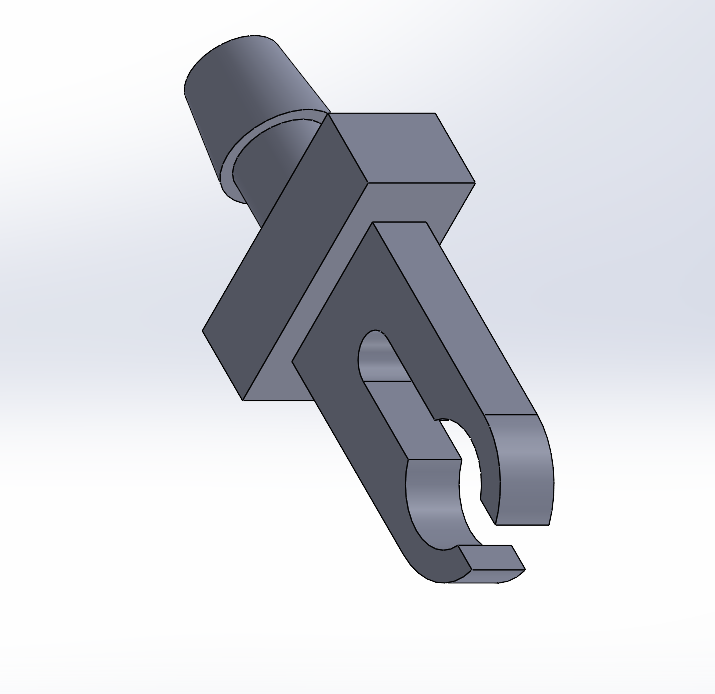

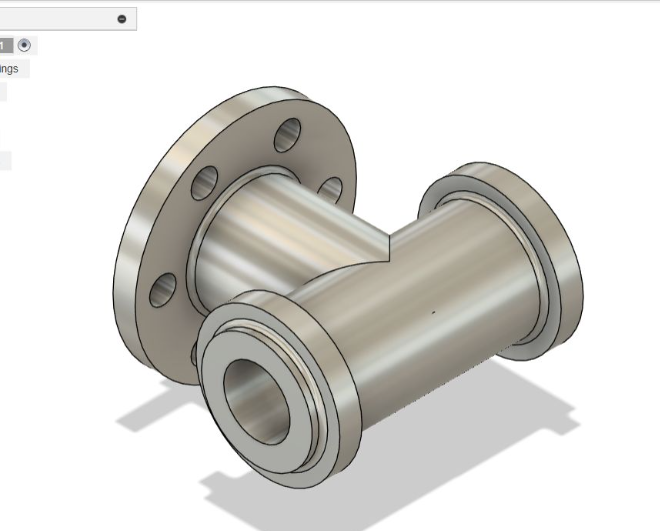

Component 1

Parametric modeling practice in CAD.

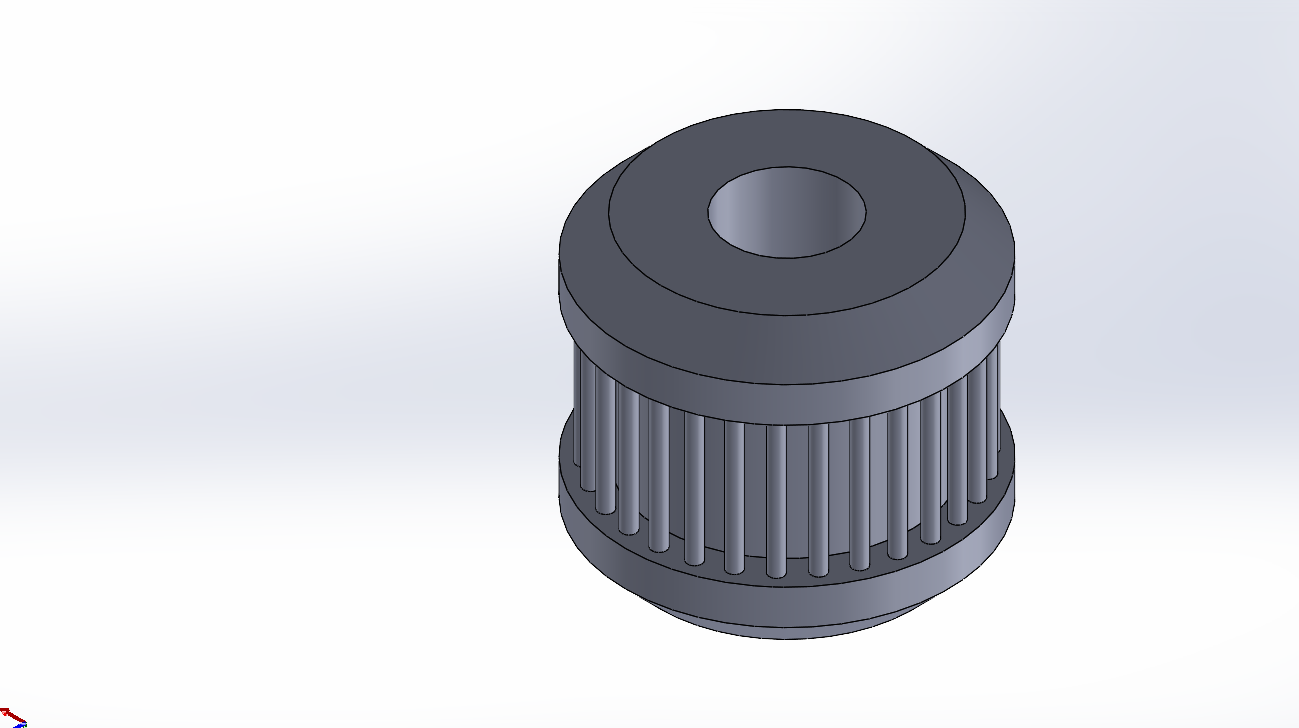

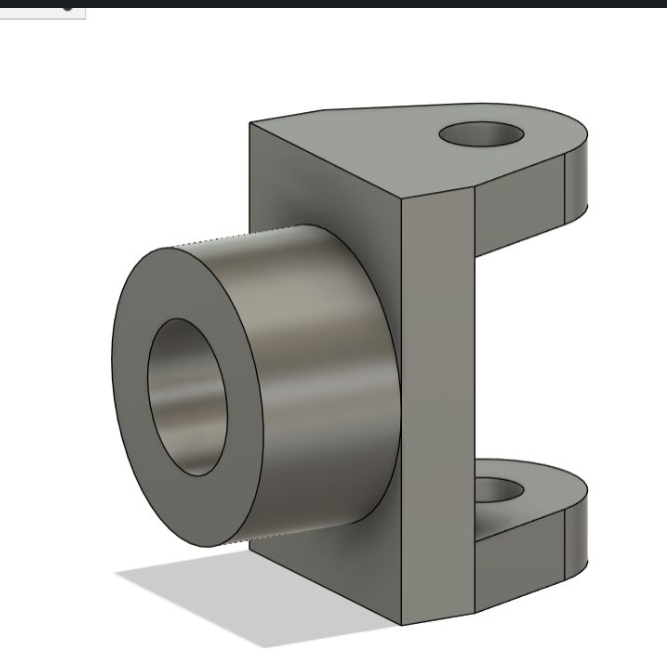

Component 2

Feature-based CAD modeling.

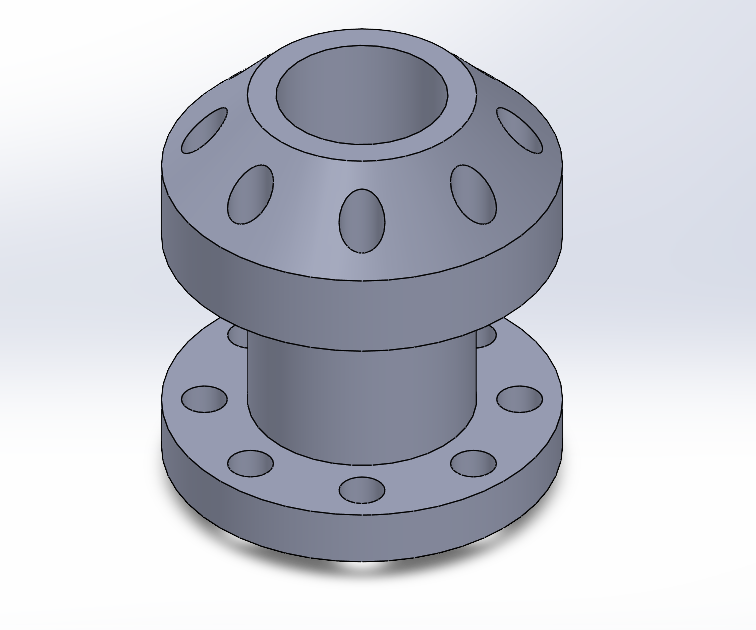

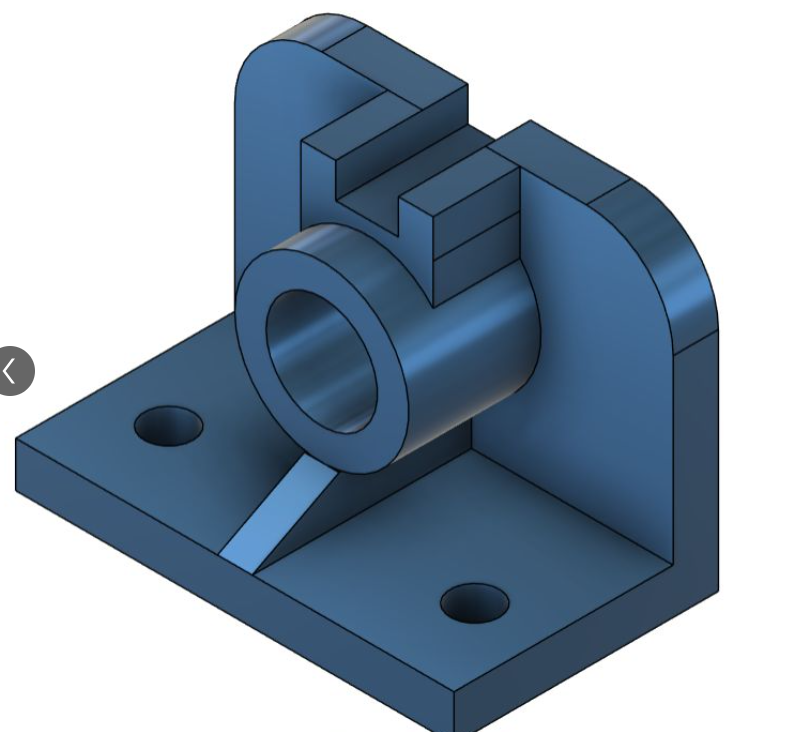

Component 3

Assembly and constraint practice.

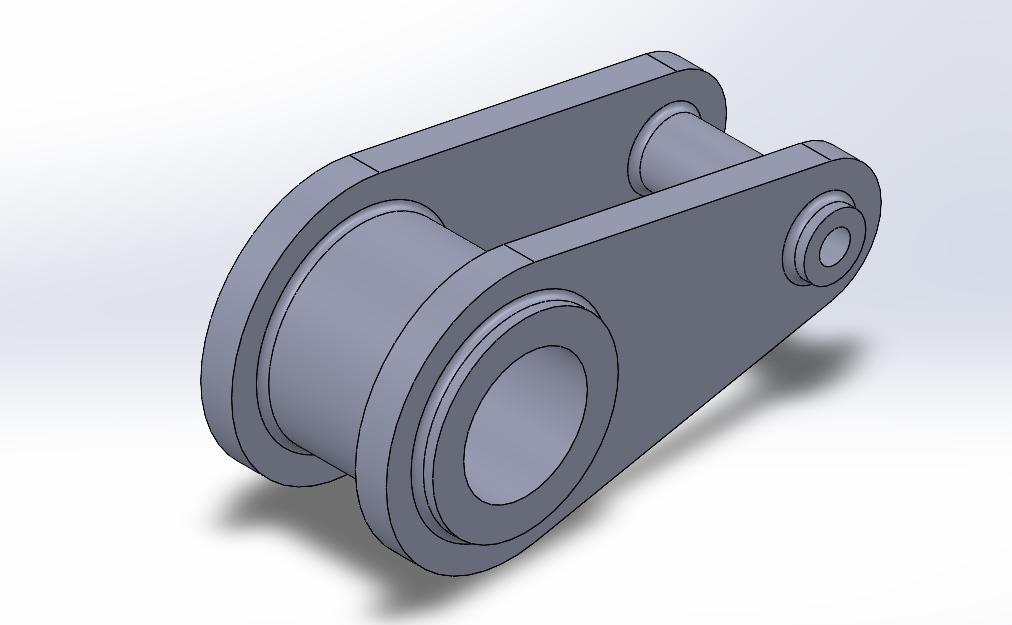

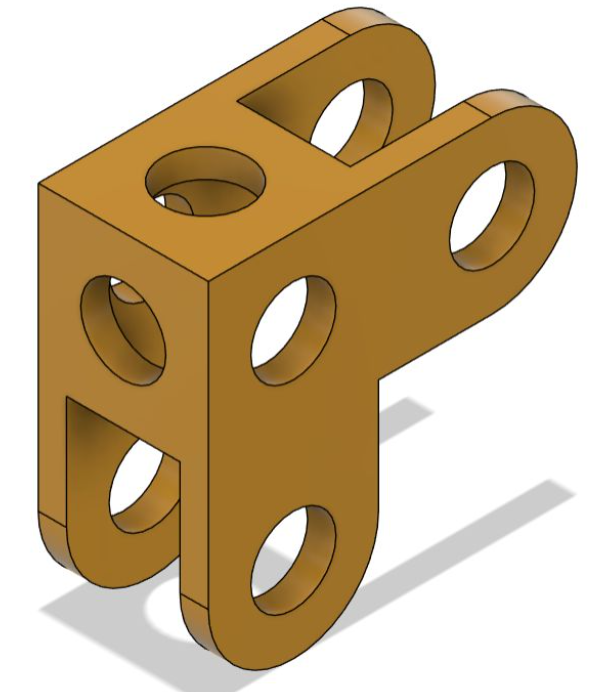

Component 4

2D/3D feature practice.

Component 5

Design for fitment and tolerances.

Component 6

Parametric design learning.

Component 7

Advanced CAD feature practice.

Component 8

Complex assembly and mating study.

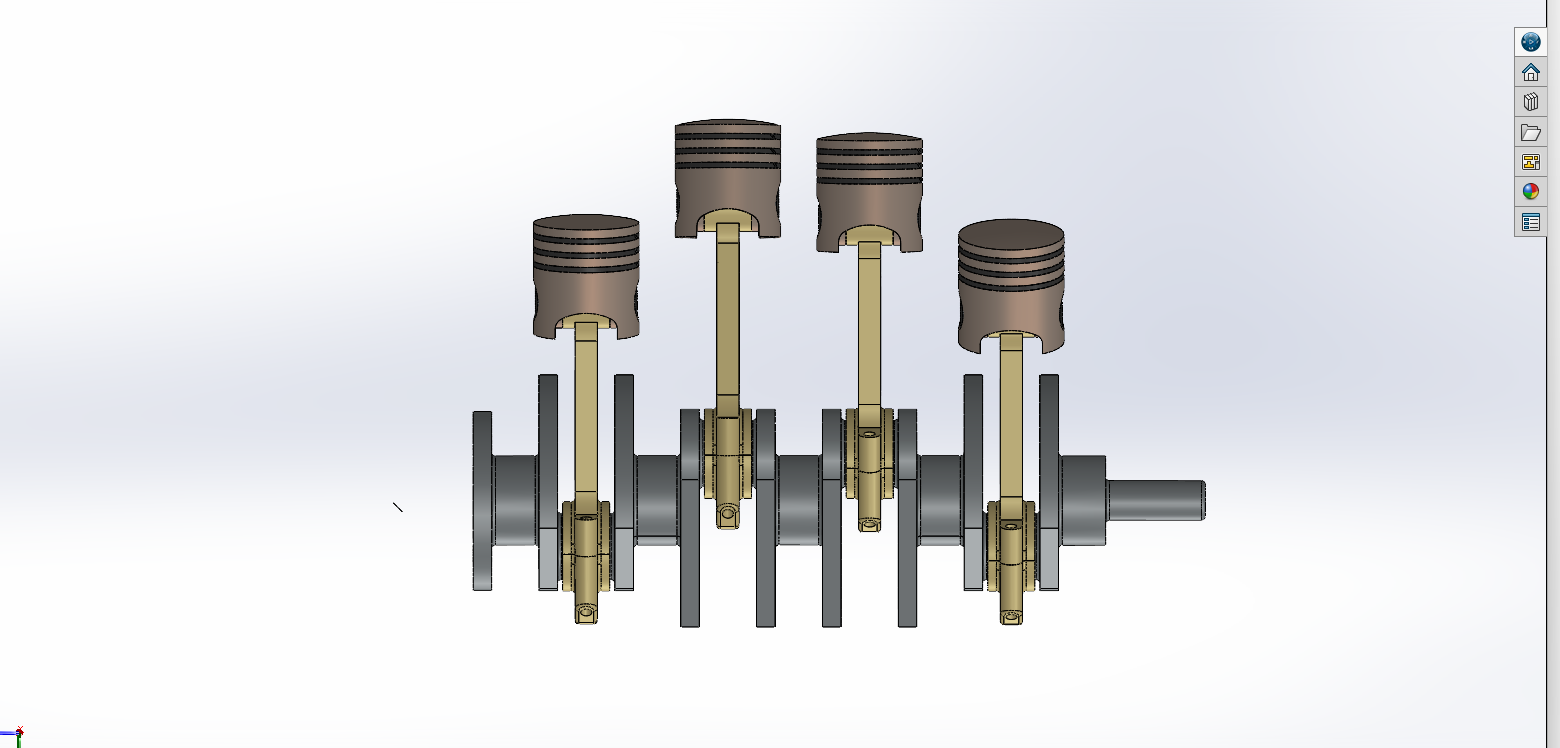

Engine

Complete engine assembly practice.

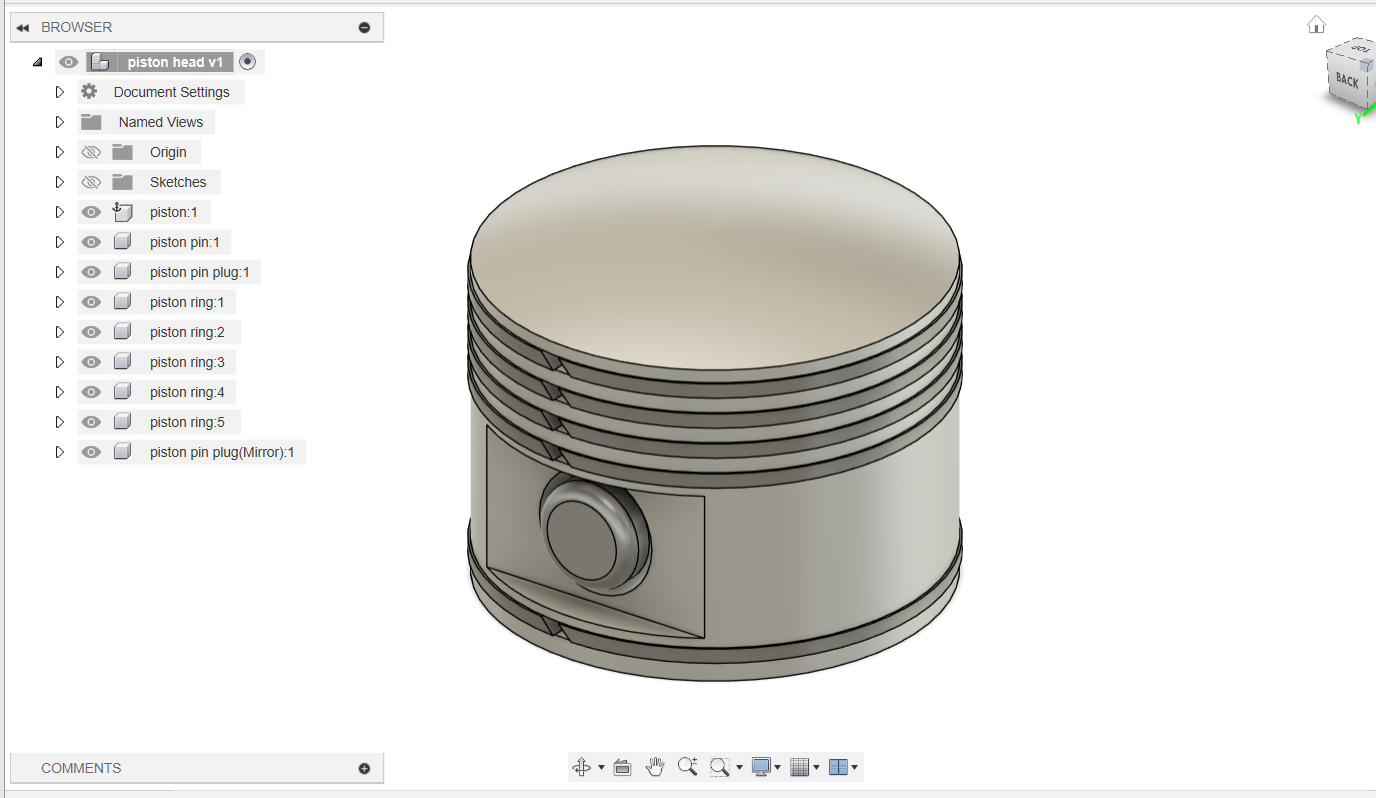

Piston Head

Piston modeling and constraint practice.

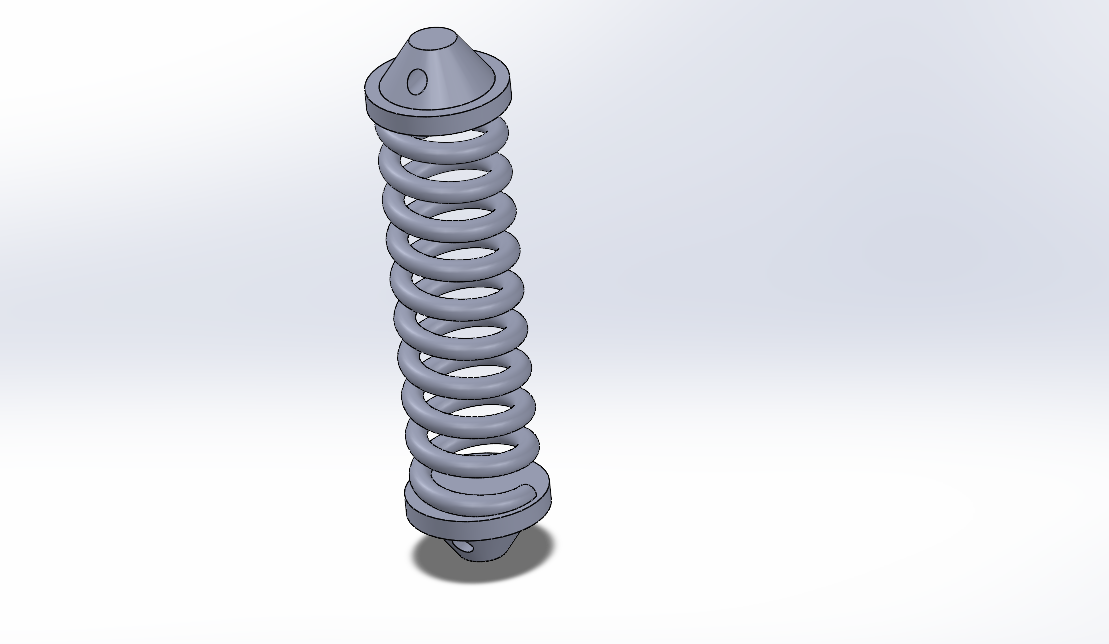

Suspension

Parametric modeling of suspension parts.

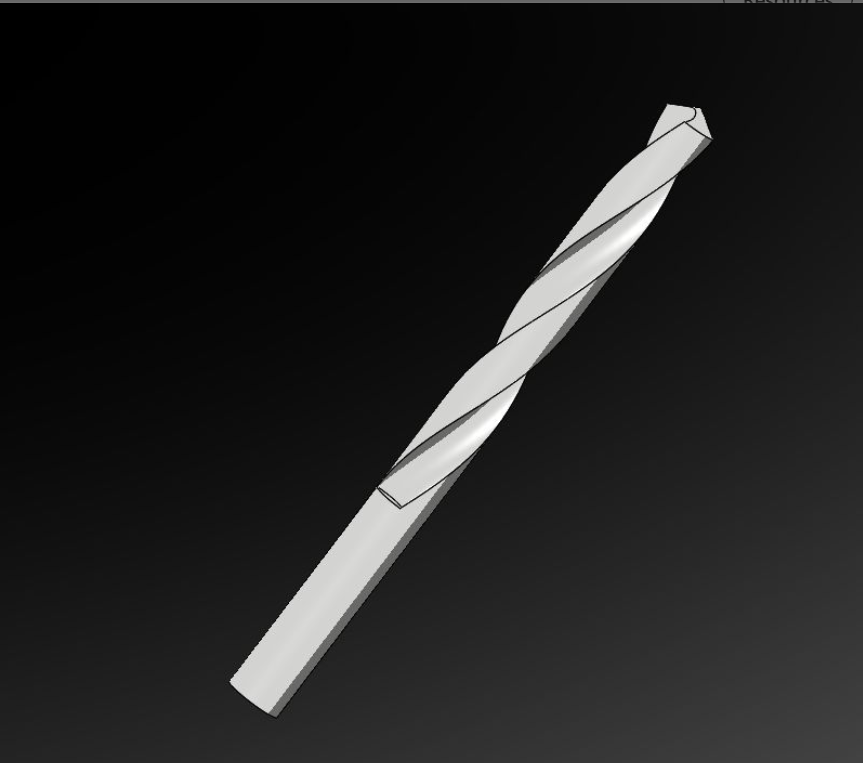

Drill Bit

Feature and dimension accuracy practice.

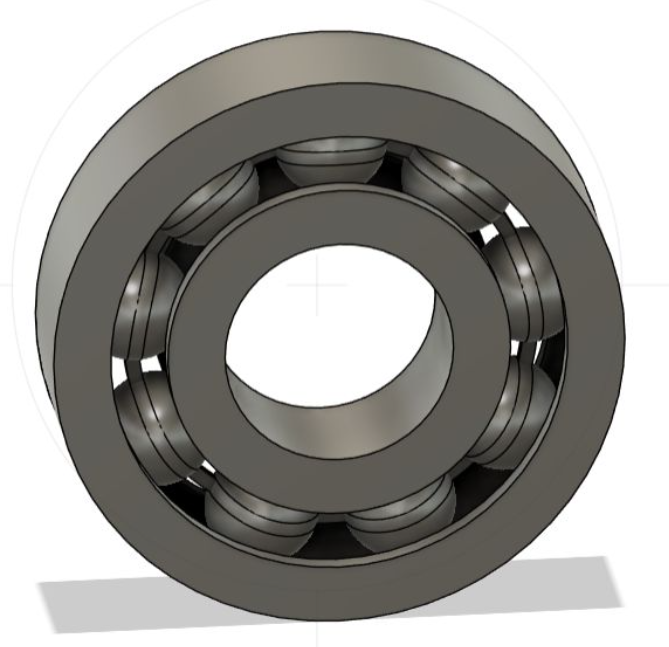

Ball Bearing

Assembly and tolerance study for bearings.

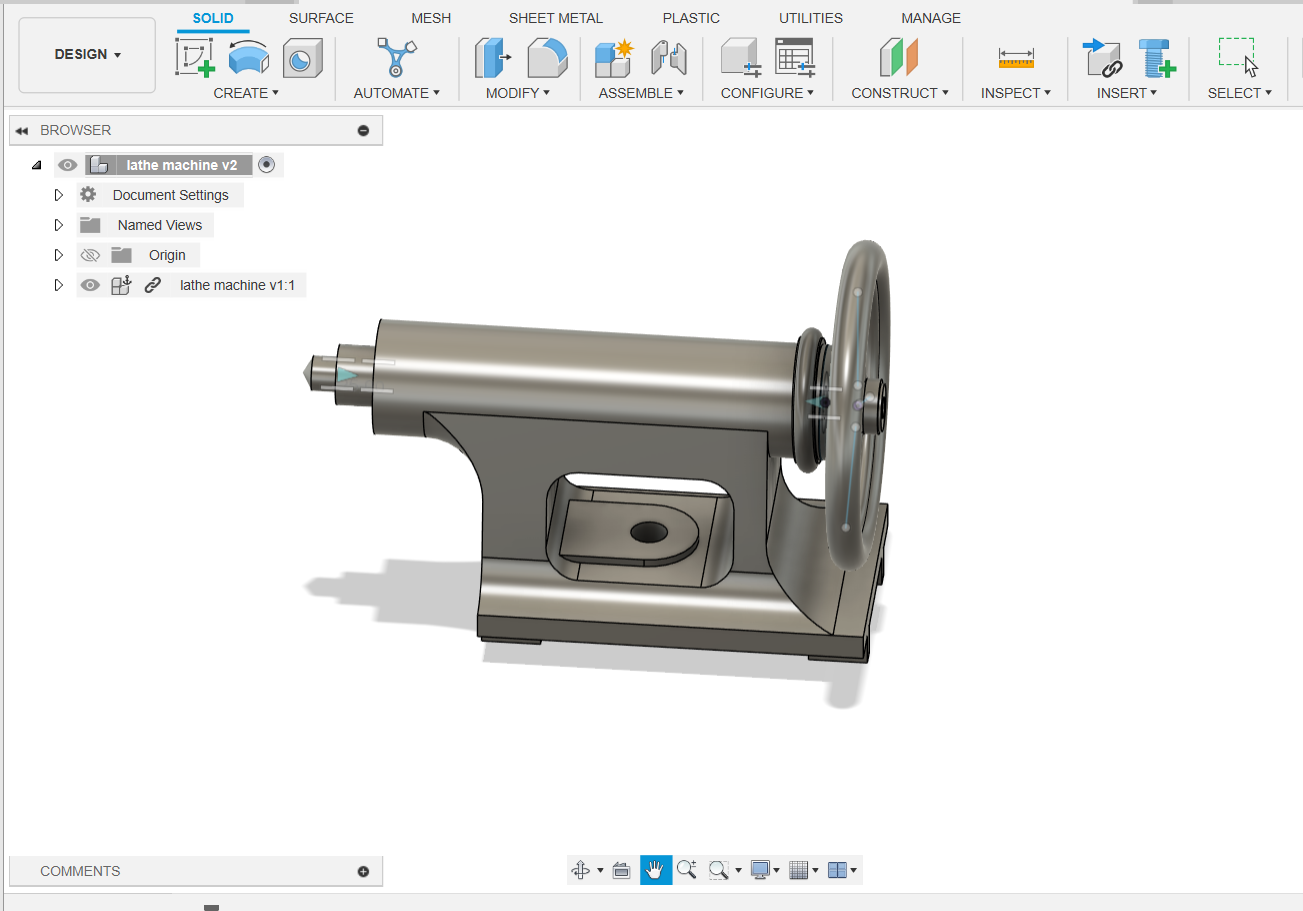

Tailstock

Component modeling for lathe assembly.

Workshops & Certifications

- Automobile Workshop — Ambal Auto (Maruti Suzuki), Coimbatore — Hands-on training covering engine fundamentals, automotive sensors, ECM functions, gear & clutch systems, and OBD-II diagnostics.

- CNC Machining Workshop — DMW Company, Coimbatore — Fundamentals of CNC machine operation, part programming (G-code basics), and practical machining workflow & automation concepts.

Memberships

- Core member — Quad Torc Vehicle Team (CAE & CAD Modelling)

- Member — Coimbatore Productivity Council (COP)

- Member — Indian Welding Society

Contact

Email: 23me005@kpriet.ac.in